|

Press Release

S & C Thermofluids Ltd has extended its affordable early design stage experimental testing capabilities by creating a UK facility for testing novel anti-icing systems in flight conditions.

The company is a partner in SANTANA: System Advances in Nacelle Techology AerodyNAmics, an ATI R&D project co-funded by Innovate UK, the UK’s innovation agency. Led by Bombardier Belfast, the SANTANA project is a collaborative programme focused on the development of aerodynamic technologies related to the design of advanced ultra-high bypass ratio powerplant nacelles. The programme targets nacelle components for next generation aircraft. Within the project there was a requirement to design and build a rig suitable for testing novel anti-ice systems within a nacelle lipskin subjected to a flight stream.

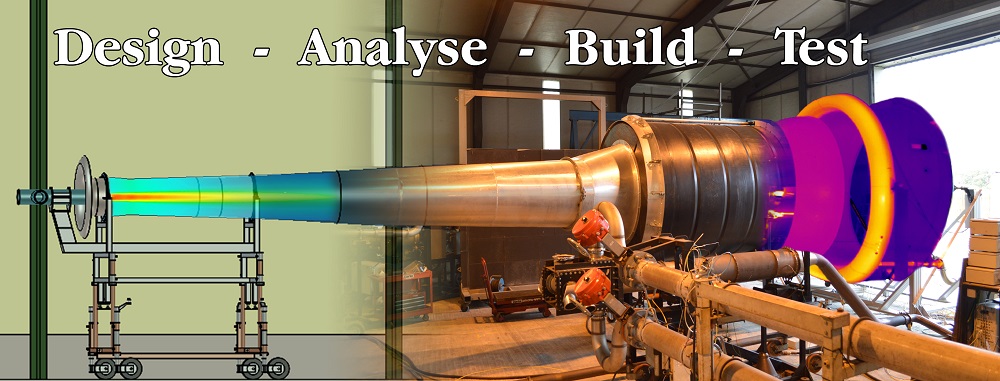

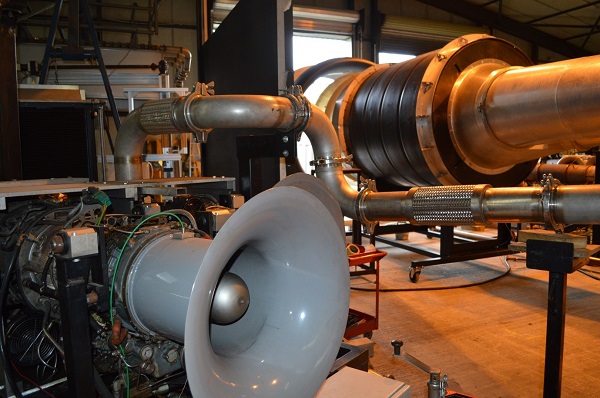

The Gnome Engine Test Laboratory (GETL), which has been operated by S & C Thermofluids since 2002, was selected as the facility to develop this requirement. The company has extensive knowledge in the experimental delivery of hot flows to novel systems and the facility has several bespoke test rigs for providing these flows at variable temperatures and pressures. The GETL’s turboshaft rigs use a Rolls-Royce Gnome engine which is loaded by a compressor, which produces compressed air as a result – approximately 4 kg/s at 220ºC. The compressed air produced can drive a number of other experimental rigs, including a helicopter downwash and flight stream simulation, and a combustor rig which can produce flows up to 750ºC.

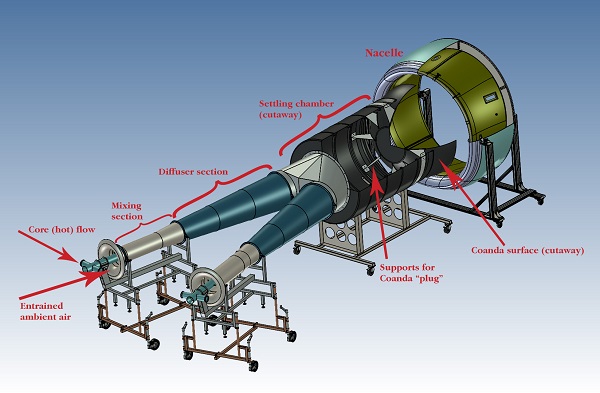

S & C Thermofluids’ existing flight stream rig can deliver a flow at a Mach number of 0.3 over a diameter of 0.5m. This involves running two Gnome turboshaft rigs and supplying the compressed air to a twin ejector system to entrain large volumes of ambient air. The two flows are then mixed in a settling chamber to lower the temperature of the compressed air, and accelerated through a flight stream nozzle.

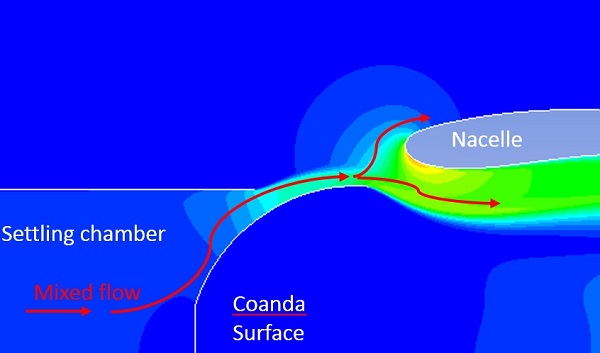

The requirement within SANTANA was to produce an annular flow capable of Mach 0.1 simultaneously across an entire lipskin surface. This was achieved by modifying the existing twin ejector system to feed into an annular settling chamber, which outputs onto a large plug. This utilises the Coanda effect to accelerate and turn the flow onto lipskin ring.

CFD analysis demonstrated that the flight stream was reaching the required Mach number, and by varying the distance of the nacelle from the Coanda surface it was possible to achieve a wash of flight stream across the lipskin.

The novel anti-icing system located within the nacelle was supplied with simulated engine flow by the combustor rig. This provides a comparable temperature difference between the anti-icing flow and the surface temperatures on the lipskin from the flight stream flow. Since all the rigs are fuelled by kerosene, continuous running allows full thermal soak conditions to be achieved across the lipskin.

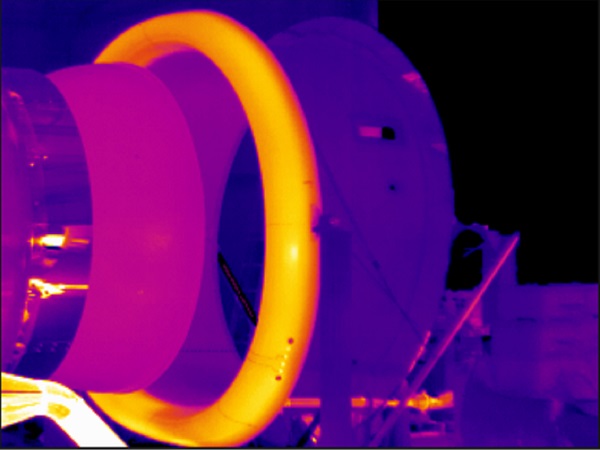

The system was built by S & C Thermofluids in early 2015 and commissioned in April. Instrumentation allows the logging of the impact of the anti-icing system on the temperature across the lipskin as well as the flight stream conditions. The GETL facilities also include a long wave infra red imager which provides a visualisation of the anti icing flow distribution.

Novel anti-icing systems have been manufactured at S&C’s Stobart Division in Redruth, and evaluated on the new test rig. Now the test concept has been proven, it is hoped that the experimental capability will be exploited for future novel nacelle systems.

About Innovate UK

Innovate UK is the new name for the Technology Strategy Board – the UK’s innovation agency. Taking a new idea to market is a challenge. Innovate UK funds, supports and connects innovative businesses through a unique mix of people and programmes to accelerate sustainable economic growth. For further information visit www.innovateuk.org

As the UK’s innovation agency, one of the main roles of Innovate UK is to achieve business and economic growth for the UK. One way the organisation supports this is through funding innovative Collaborative Research and Development (CR&D) projects. Collaborative research and development (R&D) encourages businesses and researchers to work together on innovative projects in strategically important areas of science, engineering and technology – from which successful new products, processes and services can emerge, contributing to business and economic growth. Find out more about the CR&D programme here: https://www.innovateuk.org/-/collaborative-r-d |