Press Release: CEED Innovation at S & C: Energy Game Changer |

January 2017

In 2017 S & C Thermofluids will perform a feasibility study into Compact and Energy Efficient Distillation for Tritium Recovery (CEED). S & C will lead a consortium including Flexible Process Consultants and Bath Process Consultants on this year-long activity, which is co-funded by the UK’s innovation agency, Innovate UK. The project was initiated in response to Innovate UK's Energy Game Changer competition, which invited SMEs from outside the energy sector to propose disruptive technologies or business models that will drive innovation in the energy sector by considering challenges in different ways, developing unique solutions or adapting existing technologies from other sectors.

CEED will investigate a game-changing arrangement of water distillation to achieve separation of tritium, a radioactive isotope of hydrogen, from contaminated water for nuclear waste clean up. The project team will build an experimental facility to prove the concept on a small scale and develop a simulation to demonstrate the potential to achieve up to 88% energy recovery and a significant reduction in the vertical height required for the system, compared to traditional distillation columns.

Director of S & C Thermofluids, Tony Smith, says:

“S & C Thermofluids’ main market sector is the aerospace and defence industry, where it has a track record of providing innovation alongside a cost-effective applied research capability which is both analytically and physically based. The company is keen to break into the energy sector to apply some of its skills, knowledge and new technologies to a different market.

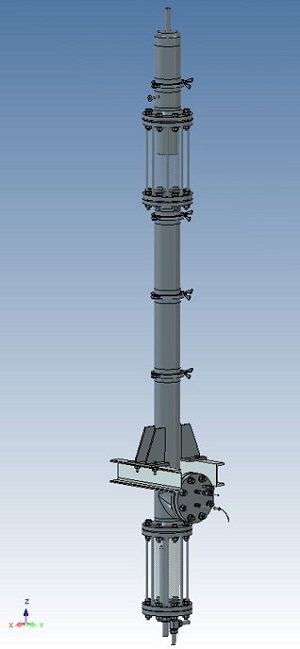

This Innovate UK initiative provides an opportunity for S & C to make that breakthrough. S & C is also keen to build on its relationships with the chemical engineering sector to form a suitable partnership which can allow it to enter the energy sector in the first instance. To this end S & C has been working with Prof Stan Kolaczkowski on a compact system for scrubbing carbon dioxide from air using water which is cascaded over a series of stainless steel Dixon rings. In working with Flexible Process Consultants, it has been realised that this technology should be transferrable to the problem of nuclear waste clean up. In particular, the removal of tritium from water is something which may be enhanced by the adoption of the compact technology from the carbon dioxide absorption system. Currently tritium is processed using very large (30m high) columns. Such systems are not very portable and are expensive to build and to commission. Using the compact system, there is a possibility that such systems could be fitted to ISO containers which could be built and commissioned (tested for functionality) off site and then deployed where the clean up is needed and readily removed on completion for use elsewhere.

Whilst the principles of the process are understood and have been proven outside the UK, there is a need to prove that the technology would work for a compact system and to do so within the UK. Within the scope of this project, the aim would be to carry out enough research to prove that the principles are fully understood and that such system is viable. Simulation techniques will enable the design and build of a test rig to investigate and prove the underlying processes.”

About Innovate UK:

Innovate UK is the UK's innovation agency. It works with people, companies and partner organisations to find and drive the science and technology innovations that will grow the UK economy.

For further information visit www.innovateuk.gov.uk.

Carbon dioxide scrubber column

Carbon dioxide scrubber column

Six chamber compact carbon dioxide scrubber

Six chamber compact carbon dioxide scrubber