Compact and Energy Efficient Distillation (CEED)

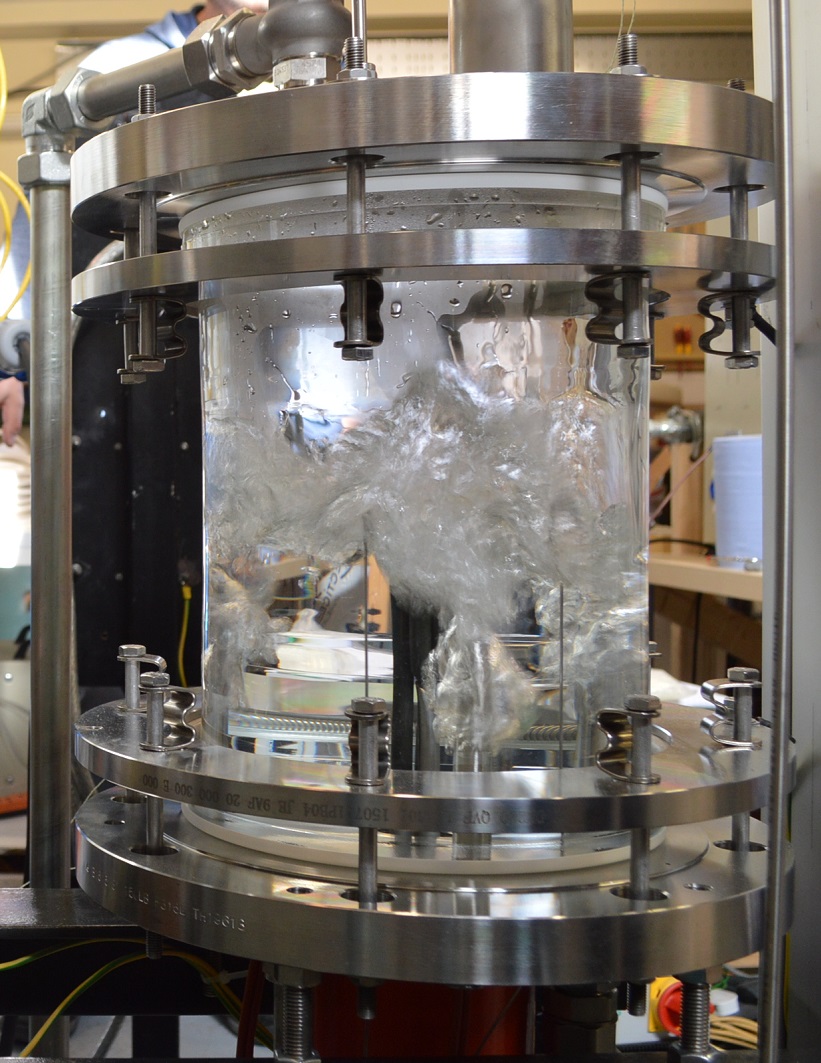

Demonstrator rig for isotope separation

April 2018

S & C Thermofluids Ltd have successfully completed a feasibility study supported by Innovate UK to investigate compact and energy efficient distillation for tritium recovery. The project was undertaken as a collaboration between S & C, Flexible Process Consultants Ltd and Bath Process Consultants Ltd in response to the Energy Game Changer competition to encourage new entrants to the energy sector and stimulate the adoption of disruptive technologies to solve long-standing challenges faced by the energy sector. In particular, CEED was focussed on the separation of tritium from waste liquid and gaseous streams - including solving the issue of storing thousands of metric tons of contaminated water at Fukushima following the tsunami in 2011.

The envisaged end product is a containerised distillation system which can be easily deployed to a site, be connected to an inlet stream and electrical power, and produce an outlet stream with tritium levels below the drinking water guideline values. This system would require no additional infrastructure as it would be commissioned offsite and transported directly to the waste stock; limited operator knowledge (with the added benefit that the operator does not need to enter the container during the treatment process); and could be re-used. It would be scaleable to any application by increasing the number of containers deployed.

The feasibility study was designed to rapidly enhance the consortium’s knowledge in isotope separation in both a simulated and practical environment, to inform the development of the end product.

The consortium consists of three Bath-based SMEs with complementary skills sets. This feasibility study was an opportunity to combine these skills and apply them to the nuclear industry.

- S & C Thermofluids Ltd is an engineering research firm with 30 years’ experience in the mechanical design, manufacture and operation of bespoke test rigs, including CAD, instrumentation, data acquisition, safety and control. The company specialises in fluid dynamics and thermodynamics, and has customers from aerospace, defence, chemical engineering, food&drink and medical applications.

- Bath Process Consultants Ltd provides expertise in the performance of experiments in small pilot-scale laboratory equipment (where heat losses can be significant), and Chemical Engineering know-how on vapour and liquid flows & equilibrium in packed columns, and the operation of columns using Dixon rings.

- Flexible Process Consultants Ltd specialises in process simulation and large scale water distillation techniques. It offers services ranging from concept validation, process design, and equipment specification, to control & trip check-out, HAZOP & LOPA support, and relief studies.

The following technical objectives of the study have all been successfully completed:

- Design, manufacture, construct and operate a distillation column capable of performing separation of HDO from H

2O under total reflux - Reduce the installed height of the demonstrator and prove that the isotope separation could be performed over a split column

- Select and obtain a suitable form of packing for the planned isotope separation trials, and to perform experiments with that packing

- Produce a simulation of the experimental setup and use it to validate and investigate the results

- Include a heat pump in the simulation to investigate potential energy savings for full scale industrial applications (up to 87% savings compared to standard boil up)

- Gain technical knowledge and understanding of isotope separation

The completed demonstration rig is currently still operational at S & C's Head Office in Bath. It has demonstrated separation across a range of inlet concentrations, which was replicated when the initial 4m column was split into two 2m sections – providing confidence towards a system with a low total height.

The consortium is now in a position to discuss potential applications of this isotope separation knowledge to more specific applications. It is expected that the rig may be developed to target end-user clean-up challenges. These may be performing additional experiments on the current rig – for example to gain an understanding of packing types and efficiency - or designing supplementary systems to better suit a specific application.

Areas of interest may include:

- Characterising packing materials

- Optimising inlet and outlet conditions for a specific process

- Waste post processing

- Development of operation and handling requirements

- Separation of other isotope species

About Innovate UK:

Innovate UK is the UK's innovation agency. It works with people, companies and partner organisations to find and drive the science and technology innovations that will grow the UK economy.

For further information visit www.innovateuk.gov.uk.

Top distributor and condenser coil

Top distributor and condenser coil

Reboiler during CEED startup

Reboiler during CEED startup

Column with trace heating and insulation

Column with trace heating and insulation