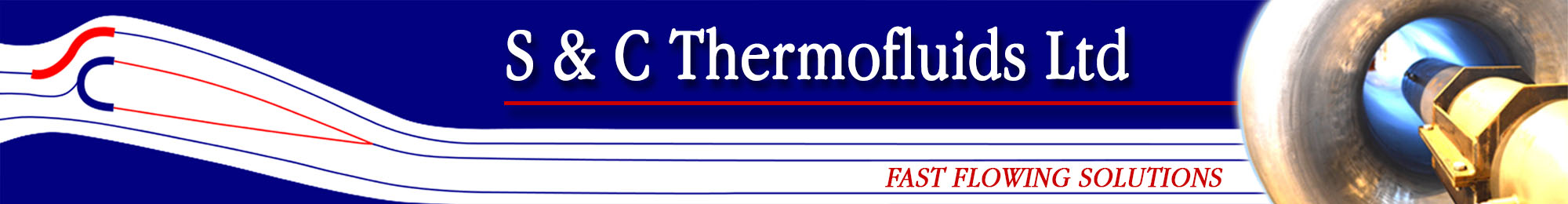

Computational Fluid Dynamics What is CFD? Imagine carrying out pressure and flow analyses to test existing structures or prototypes in a windless, simulated wind tunnel on your desktop computer. The technique is called computational fluid dynamics (CFD). |

| CFD is dedicated to solving fundamental non-linear differential equations that describe fluid flow, heat transfer, and turbulence on a computer. The process depends on the ability of high powered computers to solve millions of mathematical expressions per second in a similar way that computer-aided design and finite element analysis operate, using computational grids. CFD is used to predict how changes in these parameters affect the behaviour of the fluids and the mechanical pieces of equipment they interact with. The technology was pioneered in the UK in the 1970s by CHAM (CHAM Ltd) of Wimbledon which for many years was the only company offering commercial products. It is still one of a handful of leaders in the field. |

|

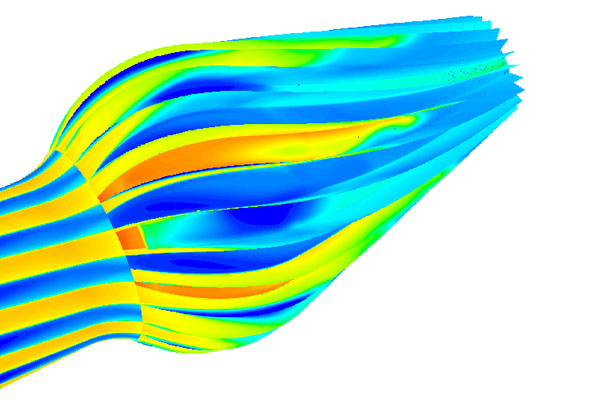

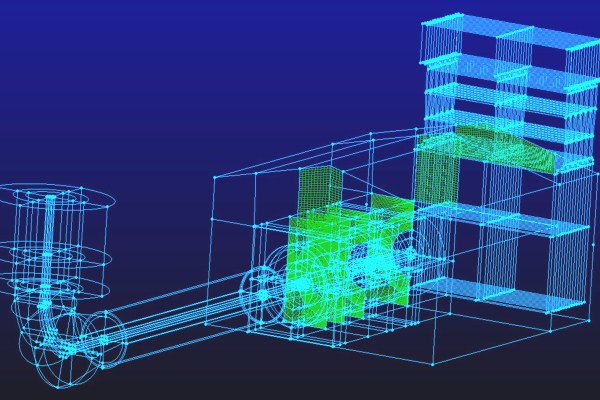

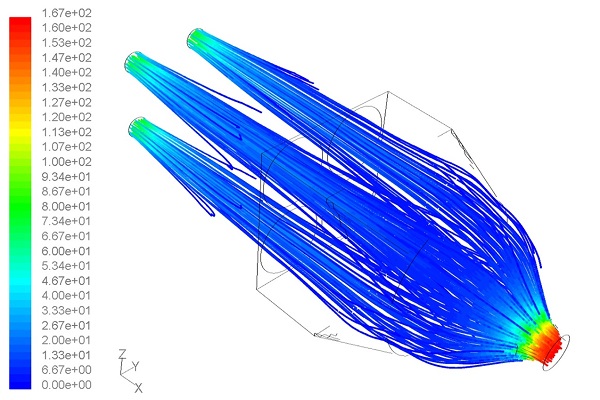

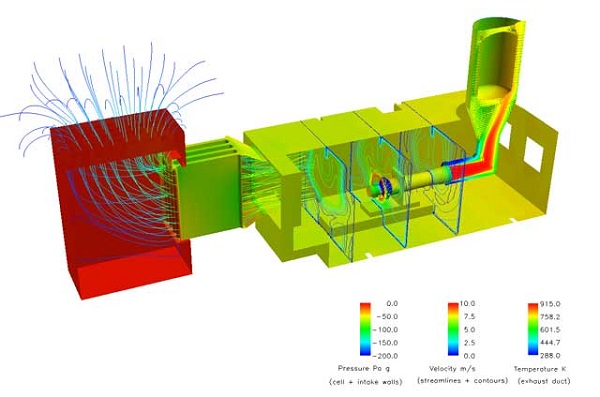

CFD at S & C S & C Thermofluids has a wealth of experience in the application of computing techniques to fluid flow and heat transfer engineering. The company applies two general purpose CFD codes - FLUENT and PHOENICS - supplemented with 3D Computer-Aided Design (CAD). Complex 3D meshes are produced using Pointwise. The following capabilities of CFD have been utilised within S & C's work:

To bolster the pre- and post-processing activities for all its analysis codes, S & C uses the FEMSYS engineering software. In particular, the software is coupled to S & C Thermofluids' infrared prediction software - FEMVIEW IR which allows the thermal energy emitted by an object to be predicted. The company uses highly developed interface software - Phirefly (by Fluxion Ltd) to transfer CAD and analysis data across a range of formats (for example FLUENT, PATRAN, Parasolid, PHOENICS). Typical applications of S & C's analysis capabilities have included:

|

|

For most CFD analysis, experimental validation and verification is strongly recommended. S & C Thermofluids provides such validation through a number of experimental facilities: our engine test laboratories, the Beck Lab and other capabilities. |