Our engine rigs S & C Thermofluids utilise a large number of engines in their test facilities, either to provide hot flows for thermal systems or compressed air to drive other rigs. The laboratory offers a low cost propulsion research capability. All engine flows can be fully data logged, and parameters such as mass flow, thrust, temperature, pressure, fuel flowrate, noise and vibration can be measured. The thrust can be measured in two axes. Laser Doppler Anemometry (LDA) and Particle Image Velocimetry (PIV) can be used to obtain detailed information about the engine flows. |

|

GNOME The Gnome engines used in the facility were manufactured by Rolls-Royce. The Gnome is a turboshaft propulsion unit. Three main variants of the engine have been produced - 1000, 1200 and 1400. The 1400 variant is used to power the Sea King helicopter. The engine comprises a free power turbine and independent gas generator. - Mass flow - 5.63kg/s |

Gnome Turbojet rig (TJ1) To provide a means for simulating typical thrust engine environments, two of the GETL engine rigs use a Gnome with the power turbine removed. The 3rd stage nozzle guide vanes which support the rear bearing have been cut back to reduce swirl and an additional vane set has been provided to reduce swirl still further. The gas generator can then be run as a turbojet engine generating some 3kN of thrust. The turbojet rigs provide from small scale up to full scale testing of nozzles depending upon the application (0.16m diameter). |

Gnome Turboshaft rig (TS1) TS1 is a very compact rig which uses the Gnome engine in its conventional format - i.e. with the power turbine. The engine is loaded using the compressor from another Gnome engine. These are linked using a gearbox taken from a Westland Wessex helicopter, and is therefore small, lightweight and contains its own oil delivery and cooling system. However the operation is limited to 19,500rpm compressor speed. The Gnome compressor is mounted underneath the engine, which makes this rig very transportable. |

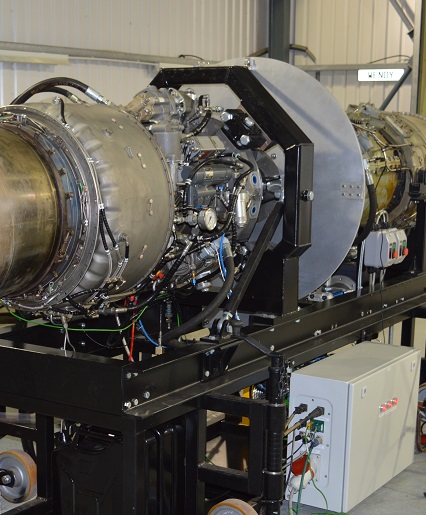

Gnome Turboshaft rigs (TS2, TS3, TS4) S&C has designed three other engine rigs which use the Gnome in shaft format and loaded by a Gnome compressor, similar to TS1, but in these rigs the gearbox has been designed to allow the engine to be fully loaded to 1235SHP. This generates a large amount of compressed air which can be delivered to other rigs. The engine and compressor are mounted side by side and there is an ancillary oil cooling system. TS3 is a variant which has been containerised to allow safe operation outside the test facilities. The turboshaft rigs can supply a compressed air flow of max 4kg/s at 220ºC, with an NPR up to 5.0. |

|

|

|

|

ADOUR The Adour engine is manufactured by jointly by Rolls-Royce and Turbomeca and variants of the engine are used in the BAE Systems Hawk, SEPECAT Jaguar and Mitsubishi F-1 and T-2 aircraft. In S&C's facility at Kemble, the Mk.104 (Jaguar) engines are used and these are run in the dry mode as a thrusting engine. Key features of the 104 engine: - Bypass ratio 0.75-0.8 |

|

TS5 (T55-Viper) Larger mass flows of compressed air can be generated using S&C's TS5 turboshaft rig, which comprises a T55 (Chinook) engine which is loaded using the compressor from a Viper 535 (from the BAC 167 Strikemaster). The shaft speeds of these two engine types are well matched, meaning they can be directly coupled without the use of a gearbox. Key features of the TS5 turboshaft: - Mass flow of compressed air approximately 15kg/s (max 18 kg/s) |

|

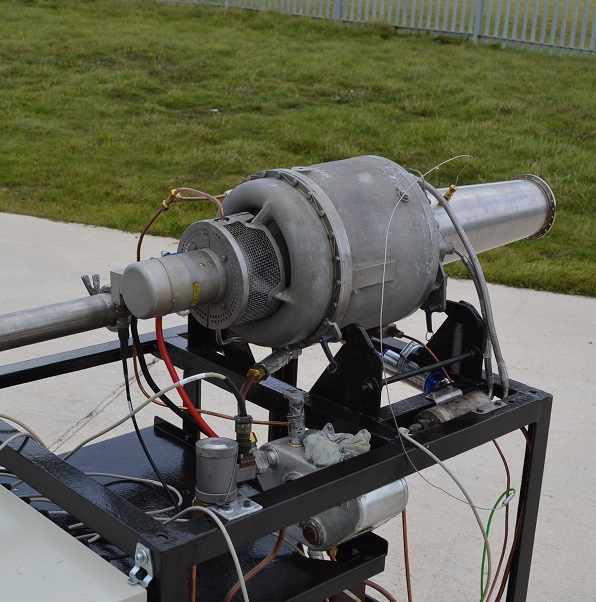

Microturbo starter (SAPHIR) The smallest of S & C's engine rigs, the SAPHIR is a very useful jet engine for low-cost scaled testing with manageable flows. The rig is based on the Microturbo SAPHIR, a small gas turbine compressor unit used to supply air for starting engines in many aircraft including the Jaguar and the Hawk. Key features of the SAPHIR: - Mass flow of compressed air approximately 0.4kg/s at 45 PSI |