Other Capabilities

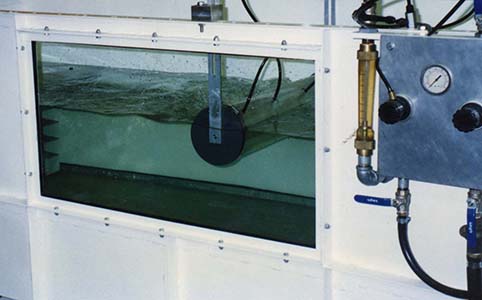

As well as the Gnome and Adour engines, S & C Thermofluids also owns and operates the following test systems to provide capability in a wide variety of smaller and non-aerospace problems.

Small scale facilities

|

|

|

Model Aircraft Research Flight testing is by tradition a prohibitively expensive process. In order to provide a pragmatic means to study and demonstrate new technologies in flight conditions, S & C Thermofluids has made use of model aircraft which are jet propelled. The aircraft is an off-the-shelf kit - The Super Reaper. It has a wing span of 1.8m and weighs approximately 7kg dry. With its Jetcat P80 turbojet engine, the aircraft has a maximum speed of 150mph (67m/s) in straight and level flight. It is controlled with standard radio control systems. The P80 is capable of generating 8kg of thrust and uses kerosene as its fuel. Typical exhaust temperatures are up to 750ºC. Flight times for the reaper are normally of the order of 7 minutes. |